The comeback of GE Appliances is a tribute to employees and customers, says CEO Kevin Nolan: "The CEO is not that important."

STAMFORD, Connecticut—In this part of New England, General Electric once made America’s most popular small appliances, before selling off that business in 1984.

Now, under the leadership of Stamford native Kevin Nolan, GE Appliances again is designing, making and profiting from made-in-Connecticut small appliances.

That local turnaround is part of a national Back to the Future-style comeback for GE Appliances. When Nolan became CEO in late 2017, GE Appliances ranked a distant second in America’s appliance market. Today it stands at No. 1.

What’s especially noteworthy is how Nolan did it—beginning with his rejection of the idea that much credit belongs to him. A proponent of what he calls Distributed Leadership, Nolan sees himself as a coach who identifies and nurtures leadership potential across his workforce, as well as among customers. It’s a management philosophy designed in part to encourage innovation, and its success is reflected in that market-share gain. Under Nolan, GE Appliances has become a true descendent of Thomas Edison, GE’s legendary founder, which shouldn’t be surprising. After all, Nolan is an engineer who holds about 30 patents.

During more than three decades at General Electric, Nolan rose to serve as Chief Technology Officer of the conglomerate’s Consumer and Industrial businesses. During that time, he came to see hierarchy as a potential impediment to innovation, customer satisfaction and overall success. In an interview with Brunswick Partners Michael Fitzpatrick and Jonathan Doorley, Nolan describes learning about an alternative to stifling hierarchy from the leadership of Haier Group—which acquired GE Appliances in 2016.

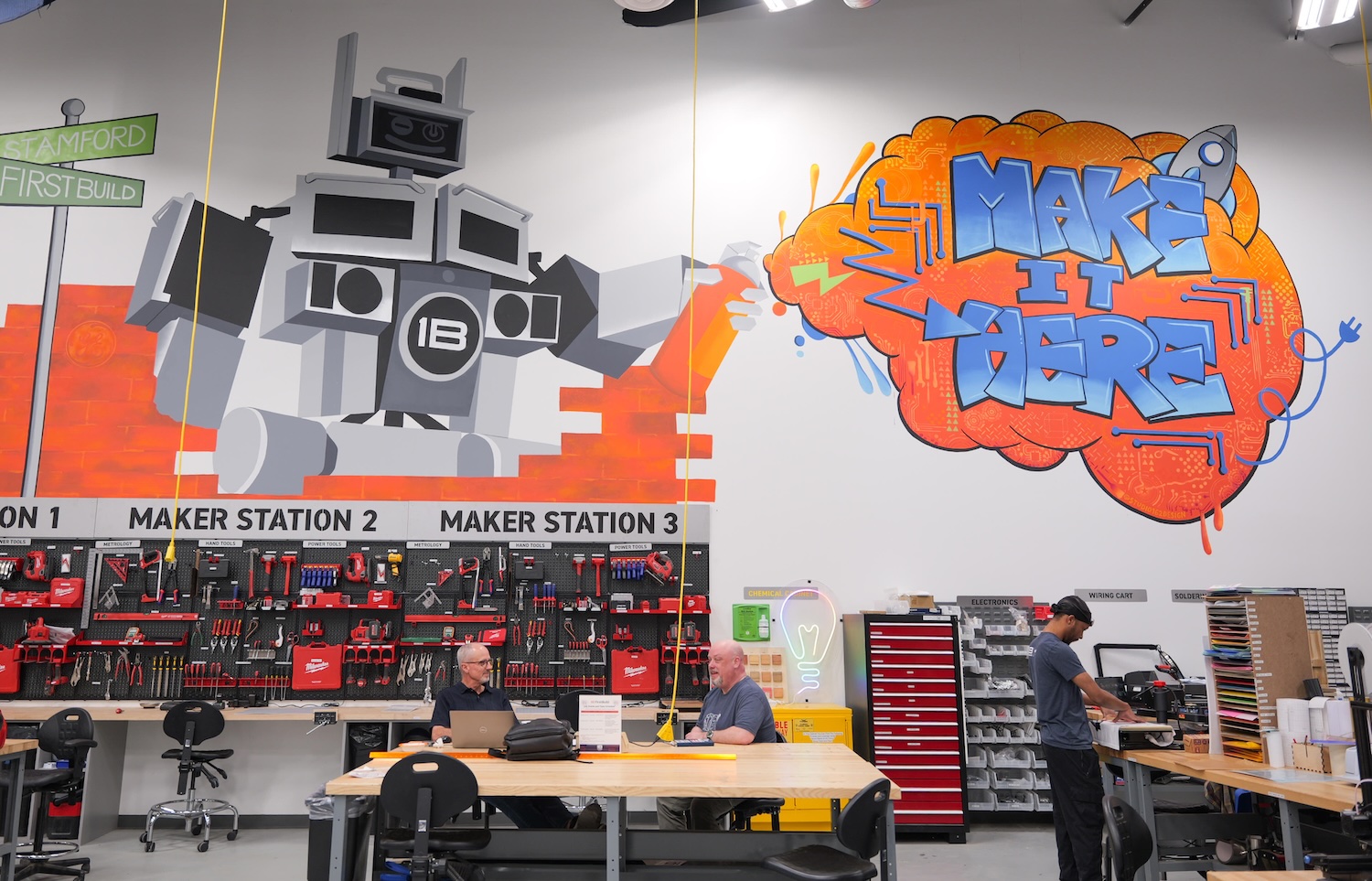

Another factor in the turnaround of GE Appliances is a strategy Nolan calls “zero distance,” which describes the ideal proximity of the company to its customers. One powerful manifestation of that strategy is the space where Nolan sat for the Brunswick Review interview. Called FirstBuild, it is a GE Appliances facility where company engineers work with the general public, including local college and high school students, to brainstorm, design and build new products. A concept first launched in 2014 in Louisville, Kentucky, FirstBuild has made rapid, low-cost innovation possible and the revived product portfolio has made a significant contribution to the rise of GE Appliances. Under Nolan, GE Appliances has leapt onto Fast Companies’ Most-Innovative-Companies list.

Can you describe the Distributed Leadership philosophy?

The previous Chairman of Haier, Founder Zhang Ruimin, created a business philosophy called RenDanHeYi. In simple terms, he had a theory that every worker does, can or should create value. We need workers to be more entrepreneurial in creating value for their customers, whoever those customers are. A company, no matter how large, should be run one-on-one. His view was that a big entity with hierarchy and structure would be better run in a nodal fashion, like the internet. He had this vision of a pure entrepreneurial company where you can use the distribution network, and use other assets of the company to create new value.

When GE Appliances first joined Haier in 2016, I studied that philosophy, and I asked, “How can we break the company down into much smaller pieces, because smaller is quicker? How do you take bureaucracy out of the system and push the power and the decision making down to smaller entities and individual employees?”

We use the term “microenterprise” to describe this approach. A microenterprise is a self-organizing unit—for instance, the unit that makes refrigerators—which is focused on market outcomes and taking what it needs out of our core services. The company becomes a platform facilitating the success of these different microenterprises.

Has it worked?

Before we put this system into place, our revenue growth was pretty flat. Since around 2017, we’ve been the fastest growing appliance company in the US. Two years ago, we became number one. With the same people, we put an entity that hadn’t grown for years on a different trajectory. Night and day.

It’s surprising and yet it’s not. Every microenterprise started having very good results and strong growth because their people had been around awhile, they knew the business inside and out, and now they could make decisions for themselves and their business units. Why do startups typically do some unbelievable things that established companies aren’t doing? Granting our microenterprises and employees the freedom and power to pursue innovation and better service gave them the feeling of a startup.

Why isn’t this philosophy used more widely?

I suspect the reason is that companies love power. Bureaucracy is what gives CEOs power, and they’re not willing to give that up. By contrast, our system fundamentally shifts that power down to where our people are making great products and serving our customers. We like to say the closer you are to the customer, the more important you are. The CEO is not that important. For us, executives enable the employees who are serving the customer.

How do you balance letting a thousand flowers bloom with the need as a CEO to ensure a level of coordination and efficiency?

How can we get the speed and the nimbleness of a startup, but with the efficiency of a large enterprise? There are certain benefits of scale, like purchasing power, that we can’t give up. That’s where we came up with the concept of platforms and microenterprise. A microenterprise is focused on something unique, a dishwasher. The focus in that microenterprise is very tightly on dishwashers.

But distribution doesn’t care which product it is. You just want the distribution cost to be as low as possible. That’s a platform, charged with making sure we have efficiency of scale.

The challenge is keeping your platforms competitive. We can’t let our platforms in HR, Legal or Marketing, for example, become monopolies. What do we know about monopolies? They lose competitiveness.

You’ve said that transparency is key to the success of a distributed leadership model. At GE Appliances, what does transparency look like?

We no longer have executive meetings. We have all-employee meetings. Keeping company secrets only with the executives isn’t the most efficient and effective way to run a company. If it’s important, we should all hear it. The first rule to creating transparency at these meetings is to talk about the compensation system. If you can’t talk about compensation, then you don’t have transparency.

We make sure that every salaried employee has a level of variable compensation. And that level of variability is based upon the same metrics applied to me or to others. Whatever your boss or your boss’s boss has as an incentive, you should know. Everyone understands that all of us have a stake in what we are driving as a microenterprise.

“Bureaucracy is what gives CEOs power, and they’re not willing to give that up. By contrast, our system fundamentally shifts that power down to where our people are making great products and serving our customers.”

Please tell us about zero distance.

The ultimate execution of it would be zero distance between the customer using our product and the company producing it.

In the digital age, customization is standard. Everyone in this room has an essentially different phone. We’ve each configured our phone to our needs. At GE Appliances, we recognize that the same holds true for people in the kitchen, in the laundry room, living their lives at home.

For us, here’s the ultimate zero distance: we make the product for you the way you want it. That’s not mass manufacturing. Mass manufacturing makes the product for you the way we want to produce it. That’s Henry Ford.

By contrast, we’re making small-scale, hyper-personalized products. Here at our micro-factory, we can produce things at very small scale, discovering and delivering on customer needs.

The micro-factory you mention is part of your FirstBuild strategy, wherein GE Appliances is tapping into the maker movement. How did FirstBuild come about?

It had its roots as far back as 2008, when I oversaw engineering for General Electric Consumer and Industrial. At that time, the old Thomas Edison businesses couldn’t have been less Edison-like in terms of innovation. We were outsourcing innovation, outsourcing a lot of manufacturing, and that outsourcing was leading us down a dark path. Our competitors were coming out with more innovative products than we had.

We had become a behemoth that was just squeezing productivity. In a big company you have a lot of gamesmanship around the innovation process. You have executives deciding which ideas are good, which are bad, and what emerges from that process typically is a product nobody wants. There was a long history here of dumb ideas by executives.

We had a discretionary budget for innovation. But in the wake of the financial crisis in 2008, and the housing crisis, what do you think the finance guys wanted to cut? The innovation budget. How to get the bean counters off my back? We came up with a crazy idea: If innovation was free, the finance guys couldn’t kill it.

We had a $2 million annual budget a year. So we shut down our existing innovation center, and we spent that $2 million doing FirstBuild, in Louisville. We worked with the city. We found some land. We worked with the University of Louisville, and we got a nice-looking facility built. We went around and studied a bunch of maker spaces, as well as startups.

FirstBuild opened to the public, especially students, and because of that we had donations of all kinds of equipment. Our thinking was, “FirstBuild’s got to make product. And it’s got to sell product. And it must break even because then finance can’t kill it.”

In 2014, we launched it, and one of the first products to come out of it was the Opal Nugget Ice Maker. In terms of profitability and revenue off an innovation, there’s been nothing like it. The idea behind small, chewable ice didn’t come from an executive at headquarters. It came from some of the students who were essentially running FirstBuild in Louisville.

We learn so much from them. There’s a bunch of young people who went on to unbelievably good jobs because of the experience they got at FirstBuild.

Has FirstBuild led to other successes for GE Appliances?

Yes. Product after product. The Monogram Hearth Oven, which came from a Long Island pizza lover who wanted a way to cook a Neopolitan-style pizza at home. There’s a combo washer/dryer that came out of FirstBuild, for people who after starting a load of wash, want to come back and find it dry. We’ve worked with the Ultra Orthodox Jewish community to create what we call Shabbos Keeper, so that your appliances help you follow and respect Jewish law.

FirstBuild is part of a larger philosophy called Co-Creation. Does co-creation represent a redefining of traditional corporate R&D?

Nobody likes to talk about it, but most R&D departments inside companies do not work. By and large, innovation comes out of startups, not 100-year-old companies like GE Appliances. Having said that, I’ll take our innovation at GE Appliances versus anybody.

I’ve been in R&D my whole career. If you look at what we’ve brought to market, if you objectively look at us versus our competitors in industry, we are much, much more innovative. Co-creation is fundamental to that.

We work with Eric von Hippel, the father of the User Innovation Theory. And von Hippel (Professor of Technological Innovation at MIT’s Sloan School of Management) has shown time and time again that true innovation typically comes from users, not corporations. The mountain bike famously wasn’t developed by a bike company.

Users are our co-creators, and co-creation is driving our R&D, guiding not only what we do but what we don’t do. I’ve seen time and time again where we launch what we think is the greatest idea ever, and consumers just don’t care. With co-creation, you know from actual users that there’s a need.

The only true form of market research is someone giving you a credit card and saying, “I’ll pay you for that product.”

Why invest in American manufacturing today?

Since 2016, we’ve invested $3.5 billion in US manufacturing, with $3 billion more to come in the next five years. Why would we do that?

It puts our factories close to our customers. If you want to buy a pizza oven you can come see it being made. And maybe get the idea while you’re here that manufacturing might be a great career.

We’ve been working on this for a long time. Our products are big. Shipping gets expensive. Shorter supply chain. The math just works. And American workers are great.

Now, manufacturing’s hard. We’re good at it. Are we great? Not yet—we still have a lot to learn. Do we have the workforce we need? We’re working in elementary schools, high schools, universities to start building the workforce we will need for the next 20 or 30 years.

Should other companies in need of a CEO think about promoting their CTO?

I’m an engineer. I know product. The last thing you should have me running is a bank. Yet for some reason, the business community doesn’t think it’s crazy for a banker to run a product company.

Our global competitors are typically run by engineers. They know how things go together, how things are engineered. And they’re tough competitors. I always love it when I see a non-engineer running a competitor of ours. I’m like, “This is going to be fun.”

What role does AI currently play in manufacturing your products?

Companies are going to win or lose by their ability to adopt AI in a meaningful manner. And at this point it’s all experimentation, because the tool is evolving at the same time we’re all trying to use it.

There’s going to be a ton of mistakes made in the process of learning to be nimble and quick with AI. That’s why I really like our organizational structure. This age of microenterprise and zero distance is built for AI, versus top-down companies.

I spend probably half my time now working with AI because I need to understand the technology. I’m a machinist by hobby. AI has made me a better machinist. I design clocks. AI has allowed me

to design better clocks. If it’s bringing me better outcomes in my hobbies, it does the same thing with work.

What level of optimism do you have about American manufacturing? And how well positioned is the American worker to meet this moment of innovation technology?

I’m glad America is finally waking to the importance of domestic manufacturing. But there’s going to be a huge learning curve to bringing it back fully, and I hope people don’t get discouraged. If you haven’t done it before, you don’t just go out and build a world-class plant. If you want to be a good tennis player, you better be on the tennis court. Manufacturing is no different.

What’s going to turn the tide is us doing it, working at it, being in an ecosystem where we can all share and talk, where people can learn what’s good, what’s not good. Being in these factories is where you get ideas. The real winners operate that way.